Factory Wastewater, Exhaust Gas, and Oil Leak Treatment

Overview of Factory Wastewater, Exhaust Gas, and Oil Leak Treatment

Regarding wastewater from factories, the Water Pollution Control Act stipulates discharge standards for each type of substance discharged from factories. In addition, with microplastics (plastic debris less than 5 mm in diameter) now recognized as a global marine pollution issue, measures to protect humans and the wider ecosystem have become increasingly important.

Regarding air pollutants emitted or dispersed from fixed sources such as factories, the Air Pollution Control Act requires compliance with emission standards defined for each substance type and facility scale.

Our Company applies its proprietary technologies to develop a wide range of products useful in factory settings.

Wastewater and Exhaust Gas Treatment

- Special fiber media that removes organic matter (BOD, etc.) and suspended solids (SS) from wastewater

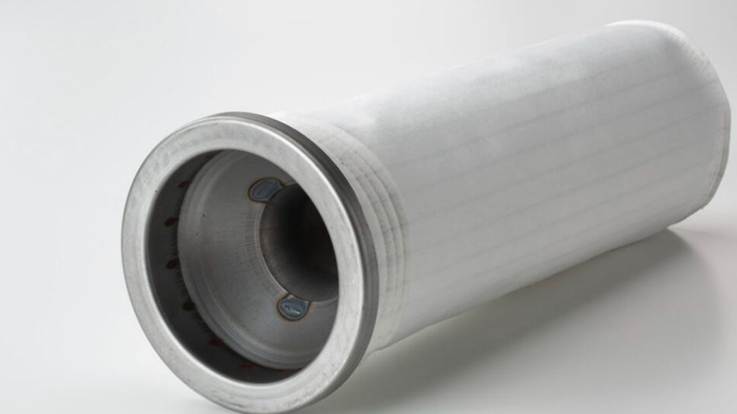

- Filters and bag filters that use ultra-fine polyester fibers thinner than microfibers as filter media

Oil Leak Treatment

- Oil adsorbent materials that capture oil leaked from machinery and piping in factories, as well as oil residues that cause contamination

Teijin Frontier’s Strengths

Product Development Capability

Our Company applies its unique technologies and expertise to focus on developing products that are useful in factories.

Here, we highlight two key products: the “Dehydration aid” for wastewater treatment, and the “Oil adsorbent nonwoven material” for oil leak treatment.

[Dehydration aid]

In Japan, a widely used wastewater treatment method is the activated sludge process, which requires proper disposal of excess sludge containing high water content — a challenge that makes treatment difficult. Our "Dehydration aid" achieves a significant improvement in sludge dewatering efficiency with a very low dosage (about 1%–4% of the sludge’s solid content). This reduces water content in the sludge and lowers the overall sludge volume, helping cut disposal and treatment costs.

[Oil adsorbent nonwoven material]

The high-performance oil absorbent nonwoven “Oil adsorbent nonwoven material” was developed in response to demand for a material that could absorb oil leaked from machinery and piping in factories, as well as oil that causes contamination.

Key features include:

- Oil absorption capacity of approximately 20–25 times its own weight for heavy oil, machine oil, etc.

- Selective absorption of oil without taking in water

In addition to factory oil leak cleanup, it is also used in restaurants and other facilities. In 2020, when a cargo ship ran aground off Mauritius and spilled large quantities of oil into the sea, our Company donated our "Oil adsorbent nonwoven material" to the Government of Mauritius, where it efficiently absorbed the spilled oil.

By focusing on current environmental challenges, we continue to research and develop innovative products.