Mobility Solutions

Overview of Mobility Solutions

Leveraging our global production network—which covers everything from yarn manufacturing through processing to delivery—for applications such as rubber-reinforcing fiber materials for tires, belts, and hoses, as well as airbag base fabrics and car seat surface materials, we flexibly meet the diverse needs of component manufacturers in Japan and abroad. Drawing on expertise that spans the procurement and processing of everything from natural fibers to carbon fibers, we can source and work with a broad array of materials. We are also focusing on next-generation R&D, such as belt cords that employ water-based adhesion processing without organic solvents, contributing to improved working environments and enhanced safety in adhesion processing operations.

Teijin Frontier’s Strengths

Development and proposal capabilities that meet even the most niche needs

Our Company possesses the technical proposal capabilities to meet even highly specialized and increasingly sophisticated niche demands. In addition to developing materials in-house, we leverage our fiber converting technologies to flexibly handle small-lot and specialized applications. Our strengths extend beyond standard materials such as polyester to include high-performance fibers like rayon and aramid, as well as their processing and product development. Furthermore, by utilizing our trading-company function—which allows us to handle products from outside the Teijin Group—we deliver optimal solutions tailored to each customer’s specific challenges.

An integrated in-house global framework that spans everything from raw materials to finished products

Thanks to an integrated framework that covers even the upstream stages of material development—yarns and fibers—we can respond swiftly to the automotive industry’s stringent quality requirements and sudden design changes. For products that demand heat and chemical resistance, we provide optimal designs starting at the fiber level, enabling flexible yet highly precise problem-solving. We have also built a management system that logs and analyzes all trouble histories, feeding the insights back into continuous quality improvements. As a technical partner who works closely with manufacturing sites, we have earned solid trust. Moreover, our global network of bases allows us to support customers as they expand overseas and to facilitate local sourcing when required.

Eco-conscious manufacturing

Our Company is committed to environmentally conscious manufacturing. A prime example is our development of belt cords that employ our proprietary water-based adhesion processing technology without the use of organic solvents such as toluene—an innovation that contributes to improving working environments and enhancing safety in adhesion processing operations. Guided by a company-wide environmental management system, we are also broadening our range of eco-conscious products across the entire supply chain, meeting the environmental requirements of next-generation mobility.

Main Products

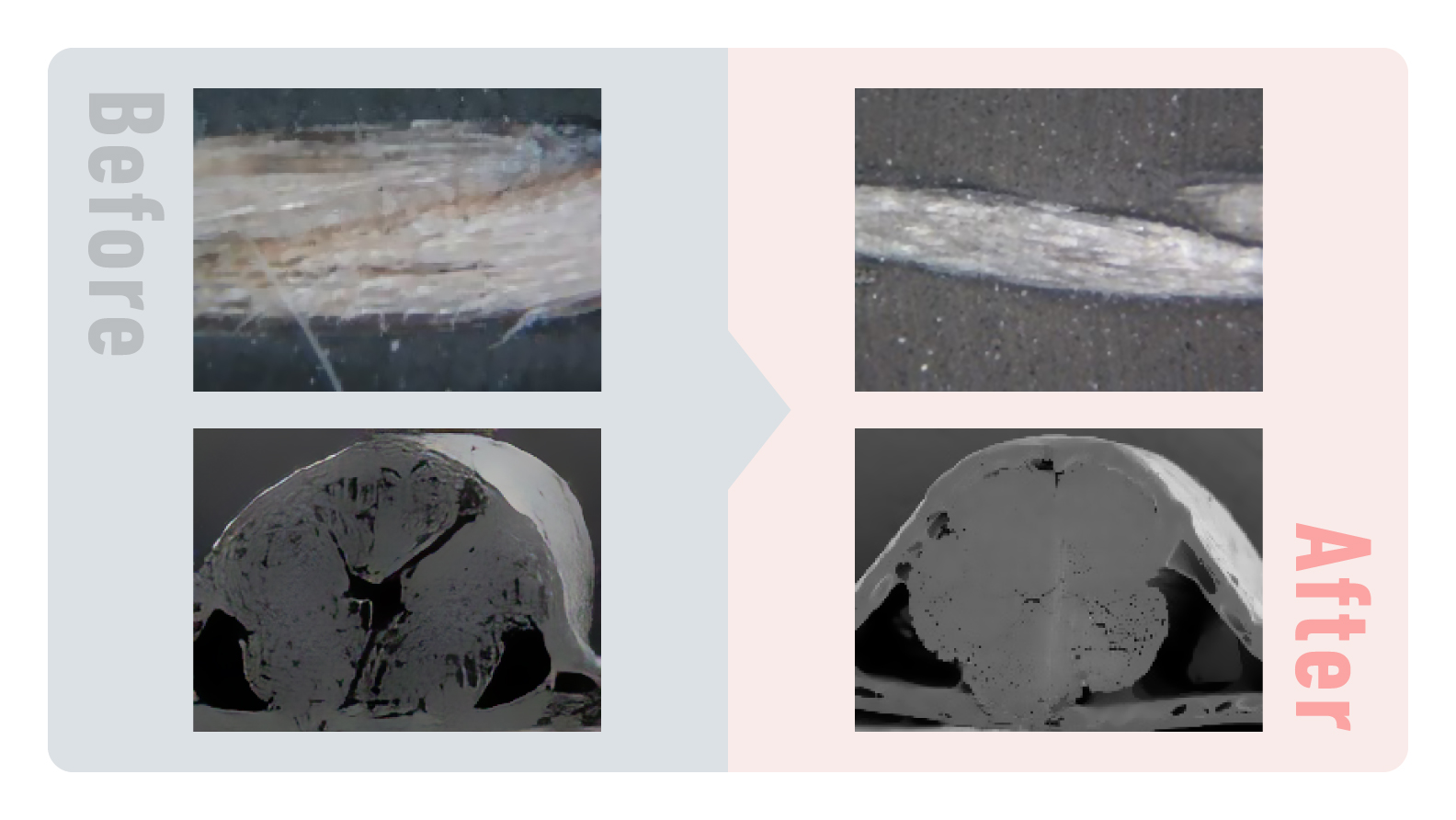

Solvent-Alternative Water-Based Adhesive for Cable Cord of Transmission Belt

This is a belt cord developed by leveraging Our Company’s many years of expertise in product development, employing water-based adhesion processing without the use of solvents in the adhesion process. In conventional water-based adhesion processing, resin cannot be uniformly impregnated between fiber bundles, leading to fiber separation. However, with Our Company’s proprietary water-based adhesion processing technology, uniform resin impregnation is achieved, effectively suppressing fiber separation. As no organic solvents are used, this product contributes to improving working environments and enhancing safety in adhesion processing operations.